100cm * 29cm * 20cm

40kg

Support Payment Term:

HSBC Hong Kong

paypal

Alibaba Pay

Western Union

USD

EUR

GBP

SGD

HKD

CNH

CAD

MXN

BRL

JPY

THB

MOP

AUD

NZD

PLN

CZK

HUF

RON

CHF

SEK

NOK

DKK

TRY

AED

SAR

ILS

ZAR

$0.00

Discover similar items

Page 1 of 2

Product Description

The automatic cutting-sealing machine is a remarkable and versatile medical heat sealing machine series product. Designed for a wide range of bag types including paper plastic bags, paper plastic three-dimensional bags, paper plastic roll bags, special strength bags, and special strength roll bags that require on-site automatic cutting and heat sealing, it offers great flexibility and functionality. The touch screen control makes it user-friendly and allows for easy operation and parameter setting.

The continuous cutting and sealing methods ensure efficient processing of roll bags. Users can set the length and quantity of single or multiple roll packaging bags for cutting and automatic sealing, providing customization options to meet specific packaging needs. With characteristics such as information storage, fast speed, high efficiency, accurate temperature control, and stable sealing volume, it guarantees reliable and consistent packaging results.

Moreover, the easy operation and multiple working modes to choose from make it adaptable to different production environments and requirements. This machine not only streamlines the packaging process but also enhances productivity and quality control in medical packaging operations.

Main Features

> Automatic feeding, cutting and sealing: You only need to set up the length and quantity of the paper-plastic pouches as per the requirements and start the program, then the machine will automatically complete the feeding, utting and sealing process;

> Touch screen with Android Os,which features in graphical operation interface,single chip control system,adjustable parameters etings with English input methods or optional scanning gun,automatic storage with functions of voice reading,voice prompt and wireless Wifi connection etc.;

> If necessary,several rolls of paper-plastic puches with different widths could be loaded into the machine at the same time to improve its working efficiency by finish cutting and sealing simultaneously;

> Temperature controlled by a microcomputer: Fast heating and high

temperature control precision;

> Safe operation:If the sealing temperature and sealing pressure exceeds setting range ,the machine will automatically stop working,which effectively guarantees the seal quality and safety.

Technical Parameters

> Control System: 7"color capacitive LCD

> Sealing Speed: 10±0.5m/min

> Sealing Width: 12mm

> Cutting Length: ≥50mm

> Cutting Speed: 20±0.5m/min

> Sealing Margin: 0~35mm adjustable

> Working Temperature: 60~220℃ adjustable

> Temperature Control Precision: ≤±1 ℃

> AC Power: According to customer requirements

Printing System Features

> Printing system can print medical device labels,marks and informations; such as the expiry date,lot No.,name or operator code,cooker No.and cooker batch

> The machine has an in-built 24-needle printer to realize high definition printing in English and it's very simple and quick;Multiple fonts(narrow,normal and wide)are available

> The operator can close all the printing functions simply by pressing one key or choose to close one of the printing functions.

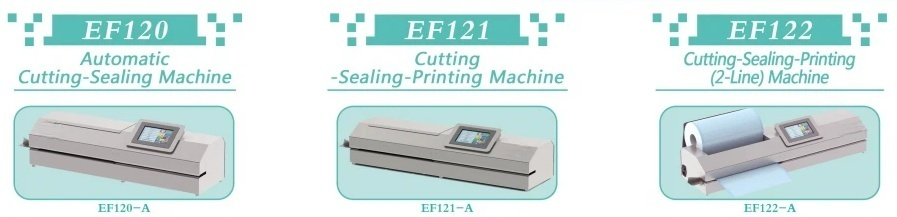

No | Model | Product Name | Specification | Max Current(A) | Fuse | Power(W) | Weight(KG) | Dimension(MM) |

1 | EF120-A | Automatic Cutting-Sealing Machine | Max Cutting Widtns400mm | 3.2 | 5A×2 | 600 | 38 | 962×290×200 |

2 | EF120-B | Max Cuting Widtn≤500mm | 3.2 | 5A×2 | 650 | 40 | 1062×290×200 | |

3 | EF121-A | Cutting-Sealing Printing Machine | Max Cutting Widtns400mm | 3.2 | 5A×2 | 600 | 42 | 1030×290×200 |

4 | EF121-B | Max Cuting Widtn≤500mm | 3.2 | 5A×2 | 650 | 45 | 1130×290×200 | |

5 | EF122-A | Cutting-Sealing-2-Line Printing Machine | Max Cutting Widtns400mm | 3.2 | 5Ax2 | 600 | 46 | 1090×290×200 |

6 | EF122-AB | Cutting-Sealing-Large-Font Printing Machine | Max Cuting Widtns500mm | 3.2 | 5A×2 | 650 | 48 | 1090×290×200 |