Product Description

Pressure Steam series sterilizer is the latest generation of Class B desktop sterilizer made by CFULL Medical . Compared with competing products of the same type, the machine is equipped with a water quality detection probe, which can effectively avoid the formation of scale in the steam generator and pipeline, which affects the performance of the machine. 3.5' LCD display, more clearly and intuitively display the steam generator temperature, sterilization chamber temperature, pressure, door lock status, program running status, time and other parameters during the operation of the machine.

CFULL Pressure Steam series sterilizer is a Class B table top sterilizer. As a type of high pressure sterilizer, it takes steam as its sterilization medium which is fast, safe and economic. They are common used in stomatology department, ophthalmology department, operating room make the sterilization for wrapped or unwrapped instrument, fabric, utensils, culture medium, unsealed liquid, etc.

Sterilization Cycles

Program

| Temp. / Pressure

| Steri. Time

| Suitable For

| SQ-Y45

| |

Metal

| 134°C/220Kpa

| 10min*

| Metal instruments

| Cycle Time* Drying Time* Load(Max) | 10~25min 15min 4.5kg |

Fabric

| 134°C/220Kpa

| 10min*

| Fabric and dressing

| Cycle Time* Drying Time* Load(Max) | 10~25min 15min 4.5kg |

Rubber

| 121°C/220Kpa

| 25min*

| Rubber and plastic

| Cycle Time* Drying Time* Load(Max) | 25~40min 15min 4.5kg |

BD test

| 134°C/220Kpa

| 3.5min*

| Bovie Dick Test

| Cycle Time* Drying Time* Load(Max) Load Textile(Max) | 3.5~11.5min 8min 4.5kg 1kg |

Advantages

▪ 7" LCD display, Touch screen

▪ Inflatable silicone sealing ring

▪ Temperature, pressure sensor

▪ Water quality detection probe

▪ USB data port + thermal printer

▪ Water ring vacuum pump + condenser

▪ 0.02um air filter device + Steam generator

▪ 3 times pulsating pre-vacuum steam rapid sterilization

▪ Intelligent mechanical lock, micro computer control

Pressure Steam Sterilization Equipments Application In Medical

Pressure steam sterilization, also known as autoclaving, is a widely used method for sterilizing medical equipment and supplies. It is highly effective and reliable, making it a standard practice in healthcare settings such as hospitals, clinics, and laboratories. The process uses saturated steam under pressure to kill all forms of microbial life, including bacteria, viruses, fungi, and spores. Here are the key applications and benefits of pressure steam sterilization in the medical field:

1. Sterilization Of Surgical Instruments

Critical Instruments: Autoclaves are essential for sterilizing surgical instruments that come into direct contact with sterile body tissues or fluids, such as scalpels, forceps, and scissors.

Reusable Instruments: Many surgical instruments are designed for reuse and must be sterilized between uses to prevent cross-contamination and infection.

2. Sterilization Of Medical Devices

Invasive Devices: Medical devices like catheters, endoscopes, and implants must be sterile to prevent infections when inserted into the body.

Diagnostic Equipment: Items such as speculums, biopsy forceps, and other tools used in diagnostic procedures are routinely sterilized to ensure patient safety.

3. Sterilization Of Laboratory Equipment

Glassware and Instruments: In clinical and research laboratories, autoclaves are used to sterilize glassware, petri dishes, test tubes, and other instruments used in microbiological and biomedical research.

Culture Media: Autoclaves sterilize culture media to prevent contamination when growing bacterial or fungal cultures for research or diagnostic purposes.

4. Sterilization Of Textiles And Fabrics

Surgical Drapes and Gowns: Textiles such as surgical drapes, gowns, and linens used in operating rooms are sterilized to maintain a sterile environment.

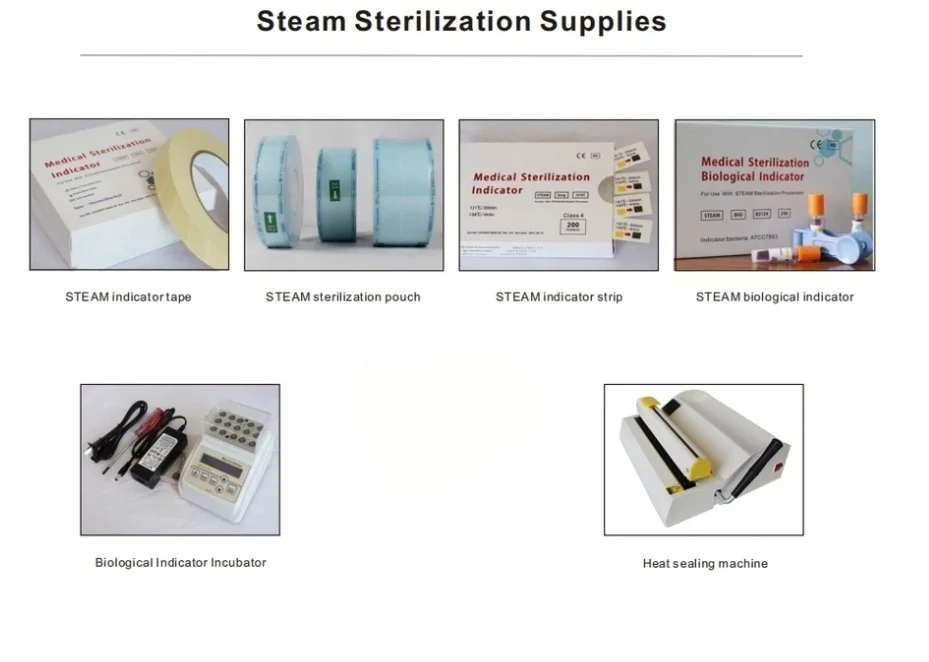

Packaging Materials: Certain packaging materials, such as pouches and wraps used to enclose instruments, can also be sterilized in an autoclave.