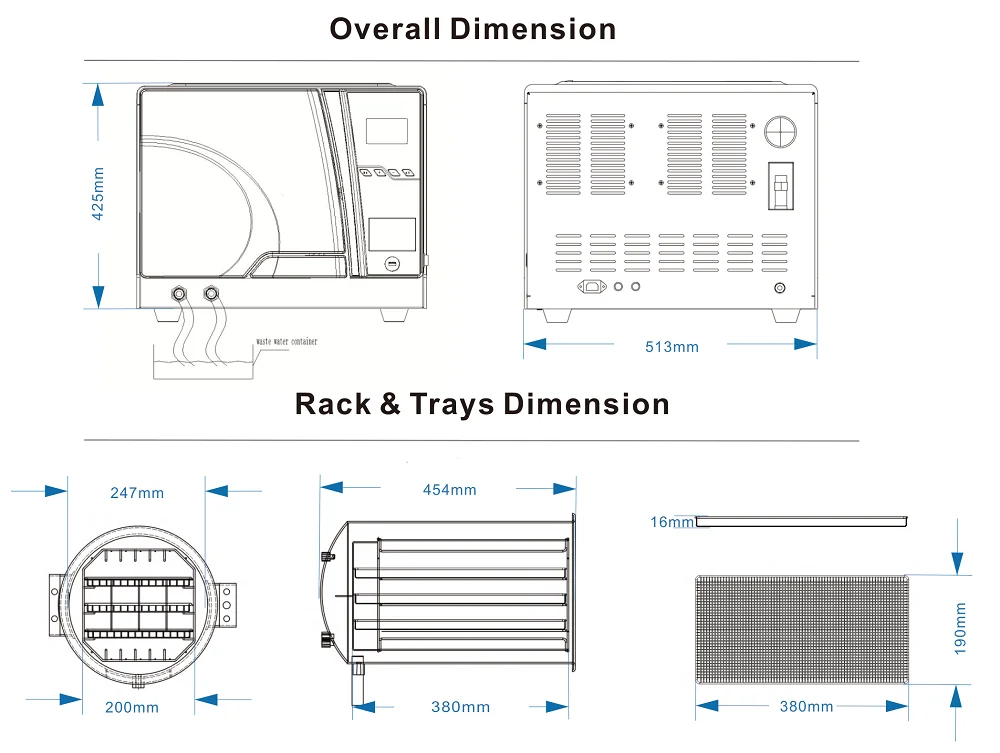

72cm * 51.3cm * 42.5cm

Support Payment Term:

HSBC Hong Kong

paypal

Alibaba Pay

Western Union

USD

EUR

GBP

SGD

HKD

CNH

CAD

MXN

BRL

JPY

THB

MOP

AUD

NZD

PLN

CZK

HUF

RON

CHF

SEK

NOK

DKK

TRY

AED

SAR

ILS

ZAR

$0.00

Discover similar items

Page 1 of 2

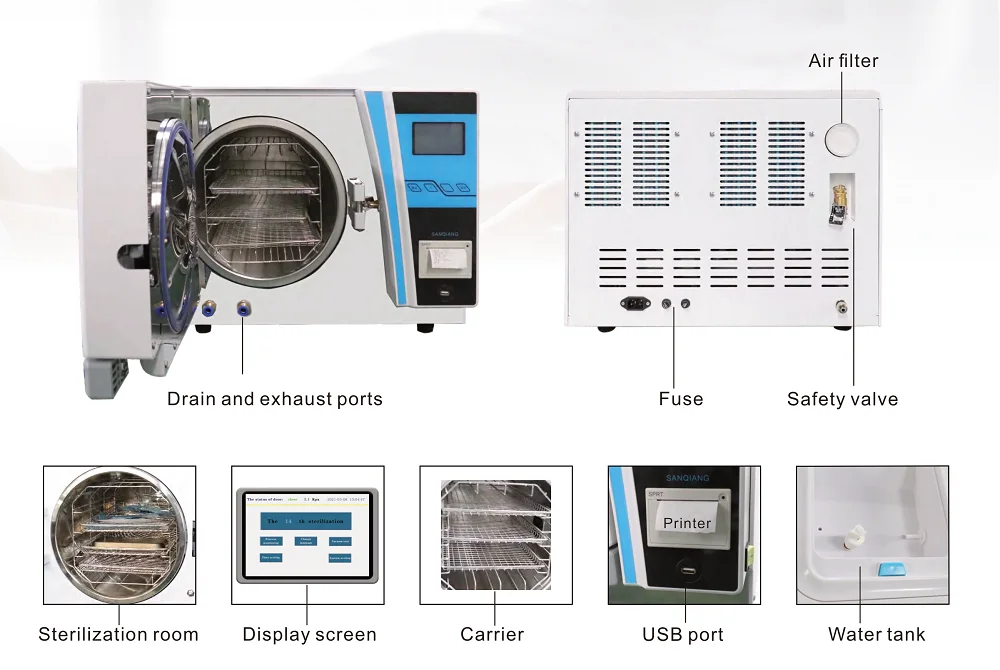

Salon Class B Vacuum Autoclave Sterilization Machine

Product Description

CFULL Pressure Steam series sterilizer is the latest generation of Class B desktop sterilizer made by CFULL Medical . Compared with competing products of the same type, the machine is equipped with a water quality detection probe, which can effectively avoid the formation of scale in the steam generator and pipeline, which affects the performance of the machine.

CFULL Pressure Steam series sterilizer with 3.5’ LCD display, more clearly and intuitively display the steam generator temperature, sterilization chamber temperature, pressure, door lock status, program running status, time and other parameters during the operation of the machine.

Technical Parameters

Name | Salon Class B Vacuum Autoclave Sterilization Machine |

Product form | table model |

Heating mode | electrical heating |

Power supply | AC220V,50Hz |

Sterilizing chamber material | The sterilizing chamber is 304 anticorrosive stainless steel material |

Outer box material | Carbon steel (thick 1.5mm) baking powder |

Work environment | 0-50℃ |

Working pressure | -80kpa~200kpa |

Sterilization humidity | ≥80% |

Maximum pressure resistance | -120kpa~260kpa |

Sterilization temperature | 121℃-134℃ |

Temperature display | liquid-crystal display |

Printer | Microprinter is used to print out every minute data during sterilization, which can be stored permanently. Ability to print records: program name, sterilization date, sterilizing pot number, start and end time of sterilization, change data of pressure and temperature of sterilization process, phase time and end state, and provide printed samples. |

Sterilization mode | It is a bare device, a packaging device, a fabric hollow, a rubber product, a BD test, and a vacuum test, respectively. |

Products Feature

1. Modes : Pre-set cycles for solid instrument , rubber ,packed device ,user definition.

2. 3.5” LCD display: modes,temperature ,pressure and other sterilization status .

3. Door safe system : mechanical and electromagnetic double lock device .

4. Pre&post Vacuum : discharging the cold air from camber ,drying the sterilized articles.

5. Post sterilization cool unit:internal steam condensate collector,and heat ex-changer cool down the post waste gas and water. Make the drainage in low temperature.

6. Internal high efficiency steam generator,with water level monitor sensor.

7. Steam generator water inlet equipped with a water quality monitoring sensor,to keep the sterilization steam clean ,avoiding the second time contamination and extending the machine service time .

8. Big volume top water tank ,can support several sterilization cycles .

9. Mini printer ,record the pressure ,temperature ,time ,alarms during process .

10. USB port , download past sterilization records to a U-disk or computer for checking.

11. Alarm : over-temperature ,water lack , over pressure , progress ending ,other faults .