About this item:

Support Payment Term:

HSBC Hong Kong

paypal

Alibaba Pay

Western Union

USD

EUR

GBP

SGD

HKD

CNH

CAD

MXN

BRL

JPY

THB

MOP

AUD

NZD

PLN

CZK

HUF

RON

CHF

SEK

NOK

DKK

TRY

AED

SAR

ILS

ZAR

$0.00

Discover similar items

Page 1 of 2

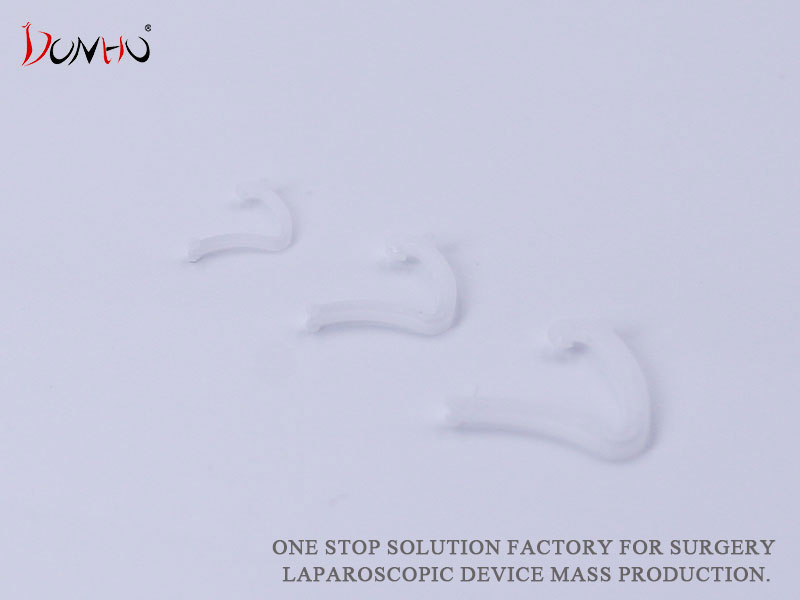

Analysis of quality control points for R&D of single-use polymer tissue closure clips for laparoscopic surgery

I. Raw material control system

Under the basic principle of ‘safety and efficacy’ of medical devices, raw material control needs to build a threefold guarantee mechanism. Firstly, establish biocompatibility file, according to ISO 10993 series of standards for basic polymer cytotoxicity, allergenicity and other systematic assessment, focusing on the stability of the material's performance before and after sterilisation. Secondly, the dynamic management of suppliers is implemented to ensure the consistency of raw material batches through flight audits, and spectral analysis and other technologies are used to establish a database of material ‘fingerprints’. Finally, a traceability system is established to form a complete material spectrum from the procurement of medical-grade raw materials to modification and processing, which meets the requirements of the quality system.

II, moulding process development

Process validation follows the progressive logic of ‘design lock - parameter optimisation - continuous improvement’. In the stage of mould development, digital mould flow analysis technology is used to optimize the design of the pouring system to ensure that the crystallinity of the products meets the requirements of mechanical properties. In terms of process control, a process window containing key parameters such as temperature, pressure and time is established, and a robust production interval is determined through statistical methods. Special attention is paid to the impact of environmental factors on dimensional stability, in accordance with the standards to establish a clean room environmental control programme, real-time monitoring of temperature and humidity, particle concentration.

III .Sterilisation adaptability study

According to the characteristics of different sterilisation methods to develop verification strategies. Ethylene oxide sterilisation focuses on the study of material adsorption on the effect of sterilisation, with reference to the standard establishment of maximum/minimum loading mode. Radiation sterilisation needs to assess the degree of destruction of polymer chain structure by radiation, and predict long-term stability by accelerated aging test. Regardless of the mode, it is necessary to perform residue analysis and establish a resolution process to ensure compliance with the safety threshold requirements of the Guiding Principles for Biological Evaluation of Medical Devices.

IV .Functional verification system

Construct a three-level verification system of ‘simulation test - in vitro test - animal test’. The basic performance verification includes mechanical index tests such as clamping force retention and anti-slip resistance, and the testing equipment conforming to ASTM standards is used to ensure the reliability of the data. The advanced validation involves the construction of an ex vivo tissue model to simulate the vascular clamping scenario in real surgery. Eventually, the in vivo degradation is observed through animal experiments to assess the tissue response level, and the relevant operations strictly follow the requirements of the ‘Code for Quality Management of Clinical Trials of Medical Devices’.

V. Risk Management Mechanism

Risk management is carried out throughout the product life cycle. In the design stage, FMEA tools are used to systematically identify potential failure modes, and control strategies are formulated for high-risk points such as the reliability of the locking structure and the visibility of the developing system. The production process establishes a statistical process control (SPC) system and implements CPK value monitoring for key processes. Clinical feedback is collected through the UDI traceability system after marketing, forming a closed loop of risk control. All activities comply with the risk management process requirements of ISO 14971 standard.

VI. Production Transformation Control

When transitioning from laboratory to industrialisation, the focus is on solving the equivalence problem of process scale-up. Through the design of experiments (DOE) to verify the scale-up effect of the equipment, and establish the process parameter conversion model. Implement design for manufacturability (DFM) to optimise the product structure, and adopt modular design concepts to improve automated assembly efficiency. Environmental Stress Screening (ESS) link simulates real scenarios such as transport and storage to ensure that the product robustness meets the requirements of YY/T 0681.15 standard for sterile barrier system.

VI ,Quality system construction

Taking ISO 13485 quality management system as the framework, establish a document control system covering the whole process of research and development. Including design and development documents, process verification reports, testing records and other three-level document system. In particular, change control management is strengthened, and impact assessment and re-verification are required for any changes in materials, processes or equipment. Regular internal audits and management reviews are carried out to ensure continuous compliance with the requirements of the ‘Good Manufacturing Practice for Medical Devices’